Ice Is Nice

Carolyn I. Schmidt

Those of you who have been to a restaurant in a foreign country, ordered a carbonated beverage and received it at room temperature probably agree with me that “ice is a nice” addition to the beverages we enjoy in the United States. We are spoiled by having ice at our fingertips in our home refrigerators. This has not always been the case.

Early settlers hung food and drink in their wells to keep them cool and from perishing. If the winters were cold enough they cut ice from nearby frozen ponds or lakes and stored it in ice cellars underground. This ice didn’t last very long. It sat in the water that melted from it, which caused it to melt even faster. The more wealthy people like George Washington had ice houses with drainage built outside their homes.

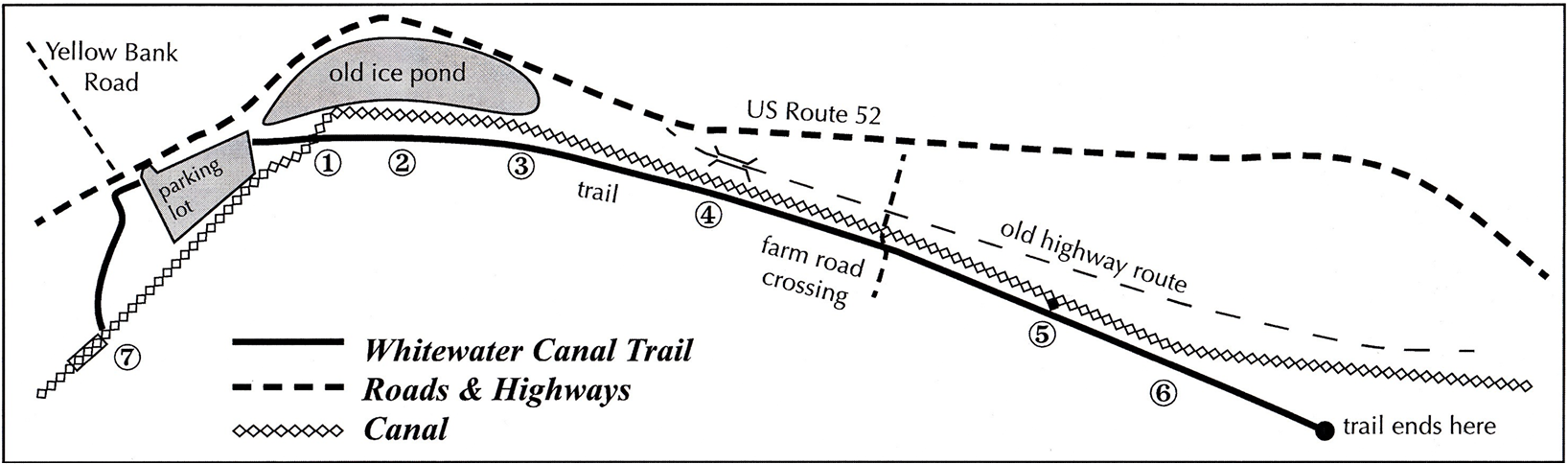

During the canal era in Indiana (1832-1872) ice ponds were built near our canals that filled them with water, which froze and could be cut into ice blocks. One of these old ponds was along US Route 52 and the Whitewater Canal Trail south east of Brookville. In the 1800s ice was harvested from this low-lying, flatbottomed area known as Hendrickson Ice Pond. Some ice pond owners stored their ice in ice houses and used the ice locally, but more was taken to Cincinnati for use by the breweries.

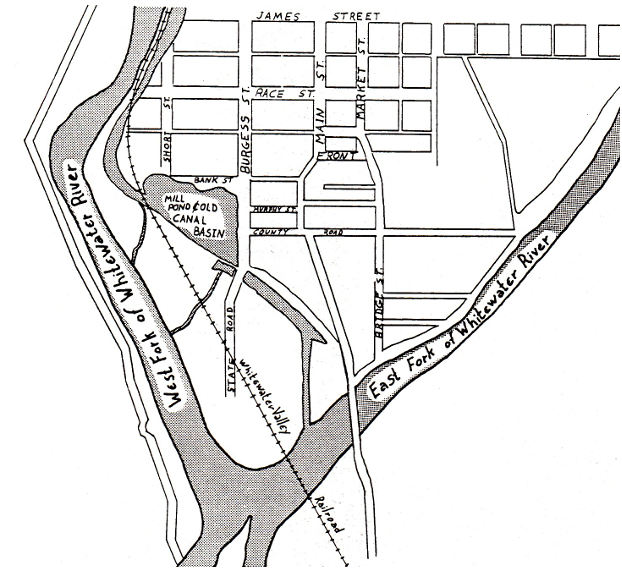

South End of Brookville

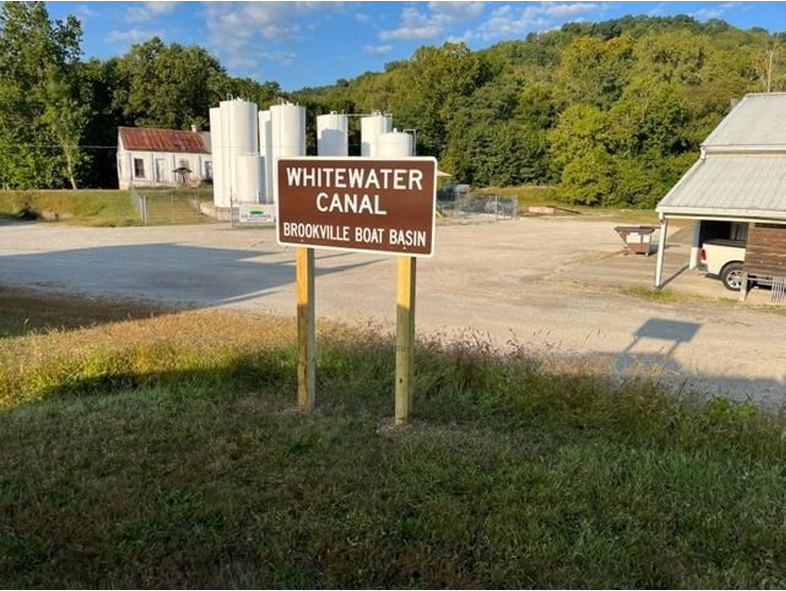

Canal basins also froze over and ice was cut from them. The Canal Basin at Brookville was noted as being a great place to harvest ice most years. It even had an ice house, which was at that time located to the far right of this picture.

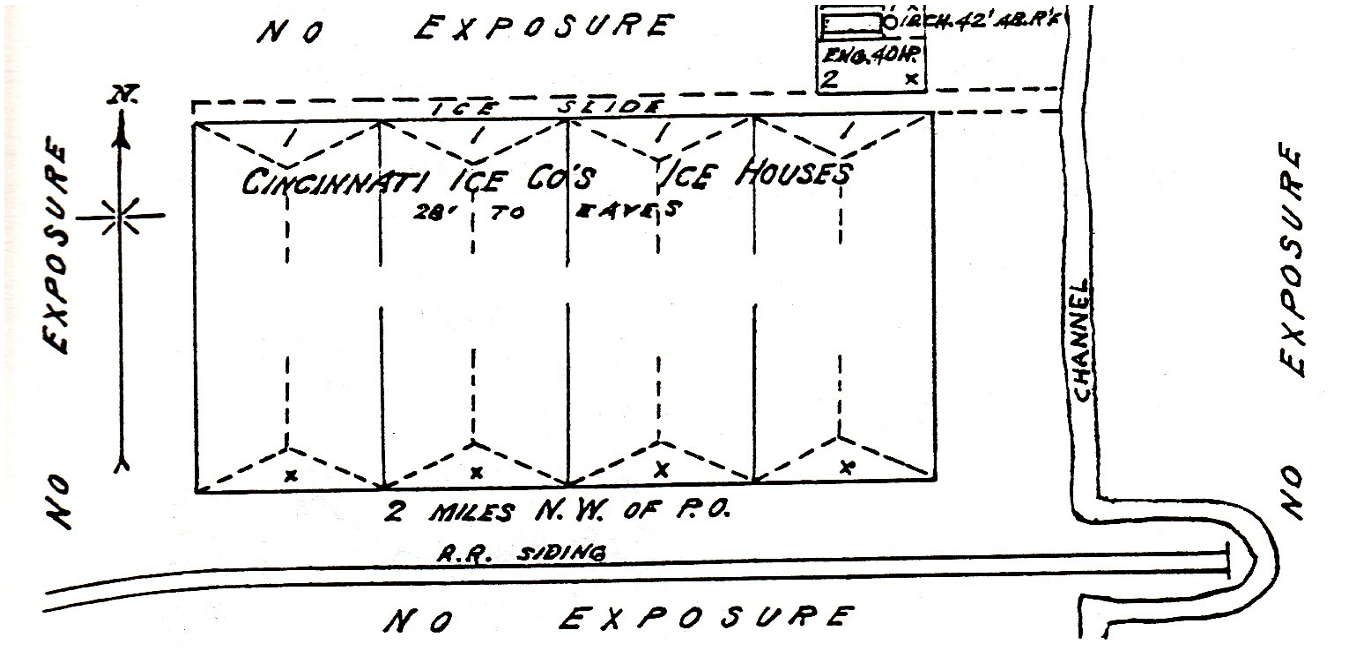

Site Plan of Old Ice House Near Metamora

This site plan shows a large ice house that was located on the Whitewater Canal half-way between Metamora and Laurel, Indiana. It was of frame construction and the double walled building was insulated with sawdust. Note that it says Cincinnati Ice Co’s Ice Houses. This company had many ice houses along the canal and sold most of its ice in Cincinnati.

South End of Brookville

Men would score the ice in the Brookville Basin in two-foot intervals and sawed it into sixteen-inch blocks. The blocks were floated to the ice house where they were stacked to make a cake of ice ten inches in thickness. The block measuring 16 x 24 x 10 inches weighed 100 pounds. It was then slid up a ramp into the ice house and packed in layers of sawdust.

During the summer months this ice sold for three to five cents per pound.

Helen Gordon reminisced:

“The ice house that I remember

was up on the head of the [Whitewater] canal, right

above the handle factory. And it had thirty two chambers

to it. And they used to cut ice on the ice pond and put it in

these chambers, and it would keep there for all summer.“People would go there and get ice to use, And, oh I don’t

know [the date] they had this so full of ice one time. all

thirty-two chambers were just full of ice. And it burnt that

night. Somebody set it afire and it burnt. And after it

burned down there was all that ice all stacked up. It stayed

for a long time to melt. People used to come there and get

ice.”

In 1908 ice was scored, cut and stored in a newer Brookville Basin ice house.

In the ice house the workers would pile the ice blocks into layers that were separated by sawdust or straw from the bottom to the top. The ice house had better drainage that the underground cellars and the ice lasted longer. Later, during warm weather, the ice was removed from the ice house as needed. In order to keep the ice house cold, they had to work quickly when removing ice from the building.

To harvest the ice, the snow was scraped off the top of it, the ice was measured and marked into blocks, then cut into floats using special saws, and the floats were pushed by pike poles through a channel to the ice house or pulled there by a horse. Larger river ice cutting operations in the northeastern states actually had conveyor belts, which were powered by steam engines that carried the blocks of ice up to the different levels in the ice house.

The ice crop from the ice ponds and canal basins was not as pure as the ice frozen and harvested from the clear, clean, cold rivers and lakes of the New England states. But the ice was not put directly into food or beverages. Instead most homes had an insulated ice box. It was loaded with a block of ice in one compartment and the perishable food was placed in another compartment. Later, fancier two-sided ice boxes were made.

Almost daily icemen made deliveries by a horsepulled ice wagon to replace the melting ice block. The homeowner would place a sign in the window for how many pounds of ice he wanted to be delivered. The iceman would cut the ice to the correct size and take it to the house. This practice of ice delivery extended into the early twentieth century. My, Carolyn Schmidt, husband’s parents still used an icebox in 1937 when they were married.

Today pure ice, which can be put directly into our food or beverages, is produced by our refrigerators or by ice plants, which sell larger quantities of bagged ice. “Ice is Nice.”

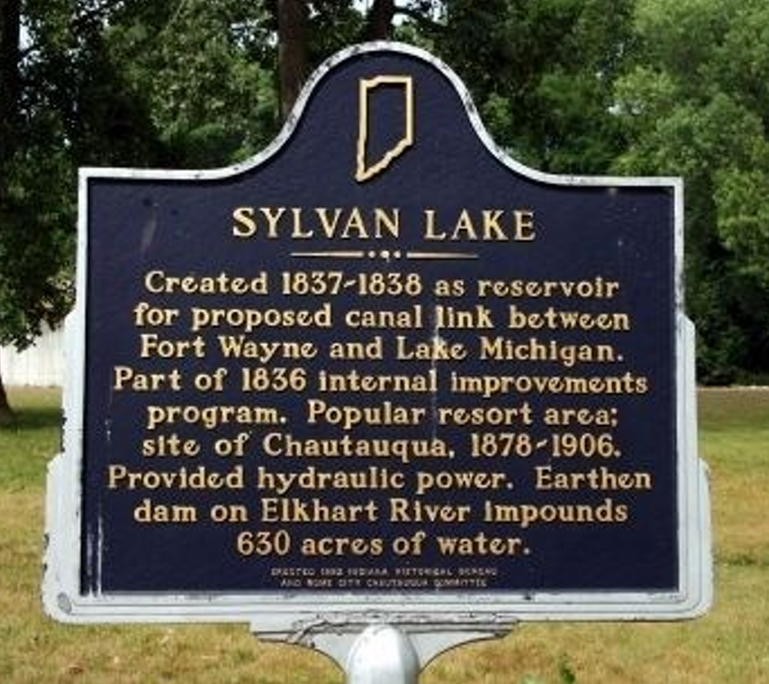

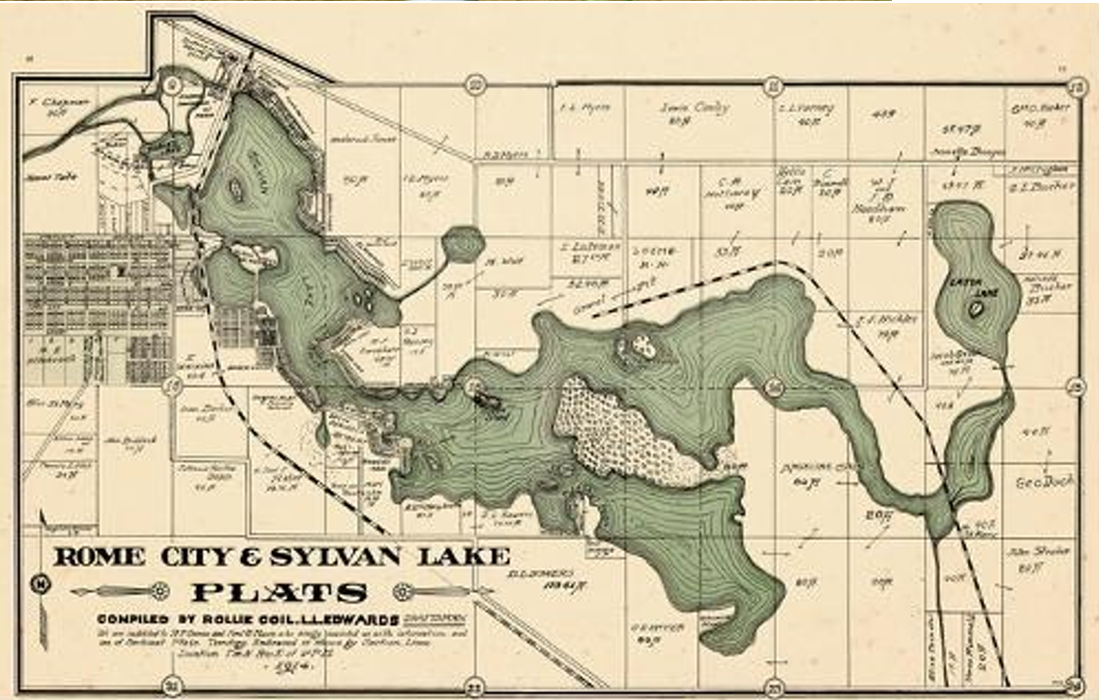

Sylvan Lake Ice Harvest

Of the 110 miles of the Erie & Michigan Canal that was authorized by Indiana’s 1836 Internal Improvement Bill, only the Northport Feeder Reservoir (Sylvan Lake), which covered 630 acres of land, and 7 miles of the canal were ever built. However, this reservoir was later used to harvest ice. The January 19, 1882 issue of the Fort Wayne Daily News reported:

“The ice harvest at Rome City began to-day. Seven inches in the thickness of the cakes. Shipments to Columbus, O., and St. Louis, Mo. have already been made. Twenty [rail] carloads will be put up daily.”

Ice Cutting Tools

Including horse-drawn implements, as many as 60 different tools were used in the 1800s to harvest ice. Hand-held crosscut ice saws measuring more than 5 feet in length and breaking bars were commonly used to finish cutting or breaking blocks of ice loose. Shown here are a few of the more commonly used tools.

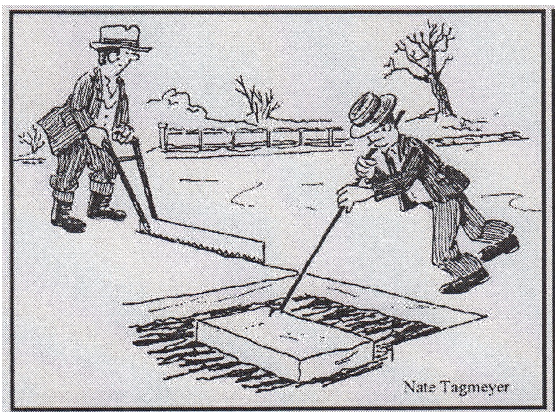

Ice Saws

A pond ice saw is very long because it needs to cut through ice that might be 18 inches thick. A good ice cutter would pull the saw almost out of the ice then lean far over to push the saw handles almost to the surface of the pond.

Chisels

The men with the saws did not need to cut out each individual ice block. It was often faster to cut out a line of several ice blocks, then have a man with a heavy chisel jam the tool into the deep groove between two ice blocks and pop them apart. The ice would usually break smoothly along the line of the groove.

Pike Poles

This tool was used to guide floating ice blocks toward the ice house. The pointed end could be used to push the ice, while the hook could be used to pull a block closer. The pole was also used to move ice blocks into place inside the ice house. Some pike poles were 16 feet long to allow a man to reach an ice block that was floating too far away.

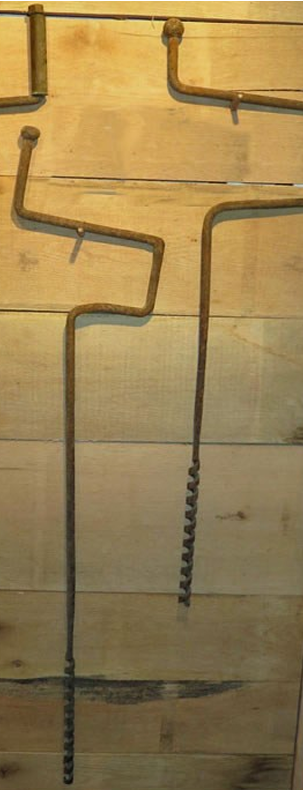

Ice Augers

The auger was used to drill holes into the surface of a frozen pond. A metal ruler with a hook at the bottom end was inserted into each auger hole to measure the thickness of the ice. The ice man would read the number on the ruler that was even with the surface. This allowed the ice cutters to know the thickness of the ice in different places and decide where to begin harvesting.

According to an article in the Connersville News-Examiner by Kate Heron,

“Men with long heavy sharp saws would cut the ice into cakes two feet long, sixteen inches wide and if ten inches thick the cake would weigh 200 pounds.”

“Houses were built for storing ice for summer use. The cakes were packed in sawdust in which the ice kept perfectly.”

“All the ice that was cut and stored by these men [Groff & Waltz] was consumed in Connersville and sold from 3 to 5 cents per pound and you had to carry it home with ice tongs.”

*The link to the right is a short YouTube video about “Ice Harvesting” on an farm in Pennsylvania Farm.